| Earthing System | |||

Earthing System

Earthing System

Deep Well Grounding System

High Silicon Cast Iron Anode

Application:

High Silicon Cast Iron Anodes have been used for many decades to protect buried and submerged structures

from corrosion. This anodes can operate effectively in a variety of electrolytes, from soil and freshwater to

brackish and salt water environments. Under normal conditions, a thin film of silicon dioxide will develop on its

surface, this film protects the anodes from metal pitting and makes them ideally suited for deep groundbed

application.

Features and Benefits:

High Silicon Cast Iron grounding rods offer a technologically superior alternative to copper grounding that

overcomes the performance dampening effect that it can have on cathodic protection systems.

☆Mitigate harmful and expensive corrosion couples between bare copper electrical

groundings and vulnerable underground steel piping and structures.

☆Reduce installation and operating costs for cathodic protection.

☆Overcome copper grounding effects that seriously compromise monitoring and control of Cathodic Protection

for associated piping and structures.

☆Withstand corrosive environments that consume copper groundings.

Ground Rod Composition

High Silicon Cast Iron Chemistry ASTM A518 Grade 3

| Standard | ASTM A518M Gr.3 | |

|---|---|---|

| Elements | Minimum % | Maximum % |

| Silicon | 14.2 | 14.75 |

| Chromium | 3.25 | 5.00 |

| Carbon | 0.7 | 1.1 |

| Manganese | 1.5 | |

| Molybdenum | 0.2 | |

| Copper | 0.5 | |

| Phosphorus | - | - |

| Sulphur | - | - |

| Iron | Remainder at 100% | |

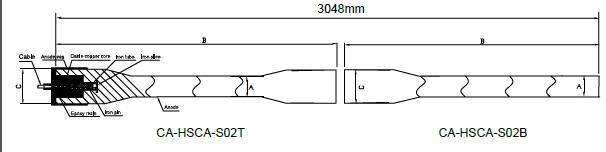

Anodes Assembly

Construction Parameters

Serial No.

|

Specification (mm) |

Surface (m²)

|

Nominal Weight (Kg)

|

|

|---|---|---|---|---|

A X B |

C |

|||

CA-HSCA-S01T |

38 x 1220 |

56 |

0.15 |

10.50 |

CA-HSCA-S01B |

38 x 1220 |

56 |

0.13 |

9.30 |

CA-HSCA-S02T |

38 x 1524 |

56 |

0.21 |

13.00 |

CA-HSCA-S02B |

38 x 1524 |

56 |

0.19 |

11.80 |